When you’re shopping for warehouse storage solutions, every single item has to bring a big return on investment, especially when it comes to crucial components like racking systems. Like most warehouse equipment, your racking system should last for many years with the right maintenance. However, with heavy warehouse traffic and constant forklift movement, your racking system will eventually show signs of wear and tear, and can ultimately impact productivity. Cracked beams, corrosion, dents, and unleveled racks can affect the stability of the structure, leading to damaged products and unsafe conditions. Need a replacement or supplement racking component for your existing system? Browse one of the largest selection of used, cost-effective replacement parts. We have used beams, decking, uprights and flow trays. Our sellers are located across the United States and Canada, call our in-house Racking Systems expert to obtain quotes, configurations, specifications and more.

When you’re shopping for warehouse storage solutions, every single item has to bring a big return on investment, especially when it comes to crucial components like racking systems. Like most warehouse equipment, your racking system should last for many years with the right maintenance. However, with heavy warehouse traffic and constant forklift movement, your racking system will eventually show signs of wear and tear, and can ultimately impact productivity. Cracked beams, corrosion, dents, and unleveled racks can affect the stability of the structure, leading to damaged products and unsafe conditions. Need a replacement or supplement racking component for your existing system? Browse one of the largest selection of used, cost-effective replacement parts. We have used beams, decking, uprights and flow trays. Our sellers are located across the United States and Canada, call our in-house Racking Systems expert to obtain quotes, configurations, specifications and more.

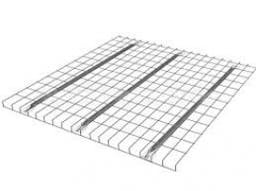

When your racking system shows signs of damage, sometimes it is good enough just to repair it, but there will eventually come a time when it will have to be upgraded. One of the greatest benefits of installing a metal shelving system is the ability to maximize the life by replacing damaged parts such as beams, uprights, wire decking, rack arms, bases, etc. Pallet rack damage is inevitable, and eventually, every warehouse will face the question of whether to repair or upgrade their racking system. Many racking systems can also be equipped with durability and safety add-ons, such as heavy-duty bracing, column protectors and wood-filled columns, for extra strength.

Even if you buy your warehouse racks used, you can customize units to suit your unique needs and space requirements since they come in so many different sizes and styles. Review your operations and space plan carefully. Switching to a different type of racking system could streamline operations and improve unloading, storage, and loading times.

Here are some signs that it’s time to upgrade your warehouse racking system:

- Are you constantly repairing your racks?

- Are your inspections routinely turning up with issues?

- Is it just your racking systems that are damaged, or do your resuable bulk containers need to be replaced, too?

- Are you running out of space?

- Has productivity started decreasing while inventory increases?

The decision to repair or replace depends on the scope of the problem. Here are 6 signs that it’s time for a warehouse racking system upgrade.